1 Single-Use Thermometer to Protect You and the Environment!

Eco-Friendly Single-Use Thermometers

Our line of NexTemp®, Tempa•DOT®, and TraxIt® thermometers are eco-friendly, easy to use, offer unsurpassed accuracy, maximum infection control, and lowest cost of ownership when compared to competitors, making it ideal for all healthcare settings. Our line of products significantly reduces the risk of patient-to-patient and patient-to-provider infection of COVID-19, C. difficile, MRSA, MDROs, Norovirus, Rotavirus other HAIs.

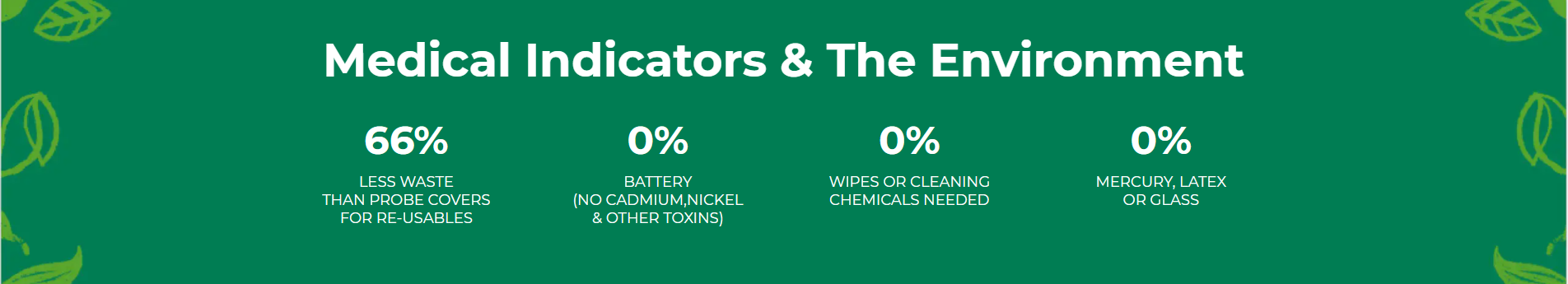

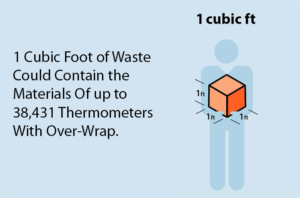

While at first glance it may not seem like single-use thermometers would be an eco-friendly friendly option, they in fact are! After calculating the waste produced by reusable thermometers, in addition to the various supplies that are also needed to safely use those thermometers, Medical Indicators’ clinically accurate, single-use thermometers actually produce 66% less waste than infrared, temporal, tympanic, and digital thermometers.

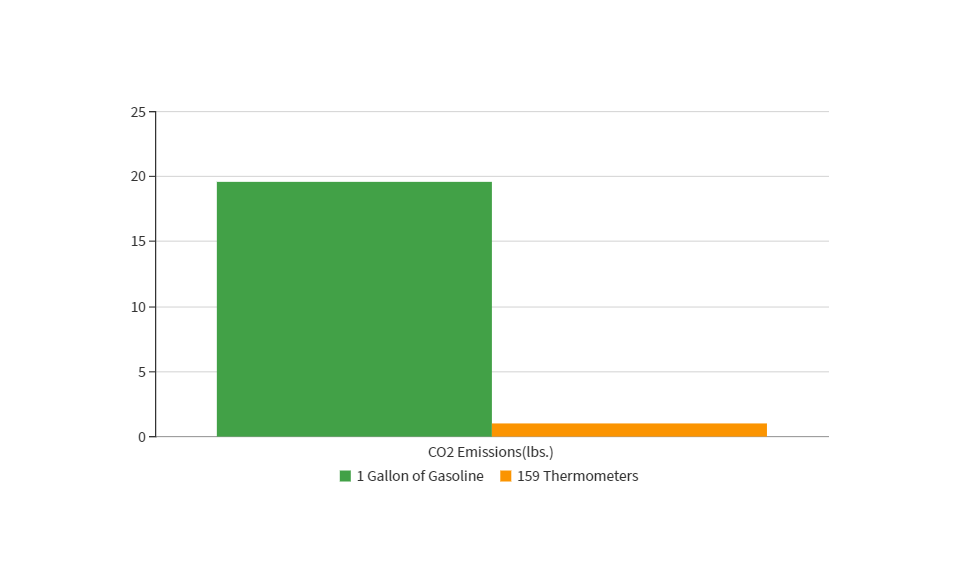

There are approximately 3.4 lbs. of carbon emissions for every 1 lb. of PET, which is the main component of our single-use thermometers. One of our thermometers in total weighs less than one gram (0.839g.), meaning that it would take more than 540 thermometers to produce approximately 1 lb. of CO2 emissions.

In comparison, burning one gallon (3225.6g.) of gasoline emits 19.59 lbs. of CO2. Therefore, it would take roughly 3,115 over-wrapped thermometers to produce the same amount of CO2 emissions as one gallon of gasoline.

Reusable thermometers require batteries, cords, probe covers, replacement parts, wipes, and harsh cleaning chemicals to disinfect the thermometer after every use.

For reference, when comparing our single-use thermometer to a digital reusable thermometer – just one disinfecting wipe that is used to clean the digital thermometer creates 9x the amount of waste as just one of our thermometers.

And that doesn’t include the actual thermometer itself, the batteries needed to operate the device, or the probe covers used with every temperature taken! These added materials create even more waste and require even more money and labor to maintain reusable thermometers. However, none of those supplies are needed with any of Medical Indicators’ thermometers.

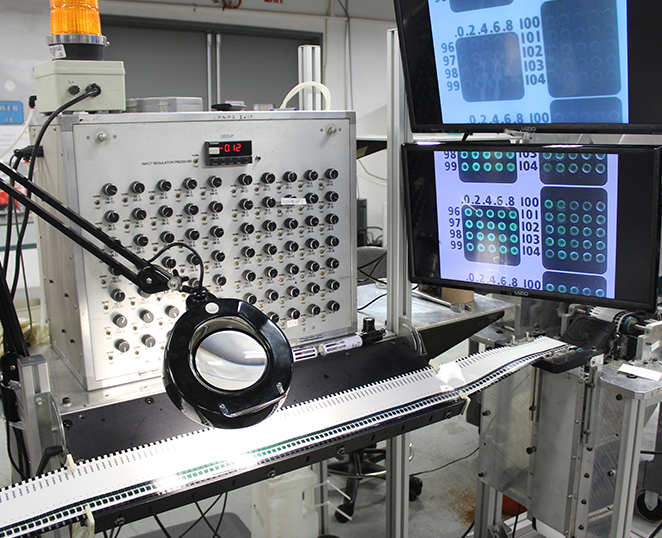

Medical Indicators’ single-use thermometers are made possible by a remarkable innovation called Precision Phase Change Technology, which uses heat-sensitive crystals to measure and display body temperature – delivering unsurpassed accuracy and reliability.

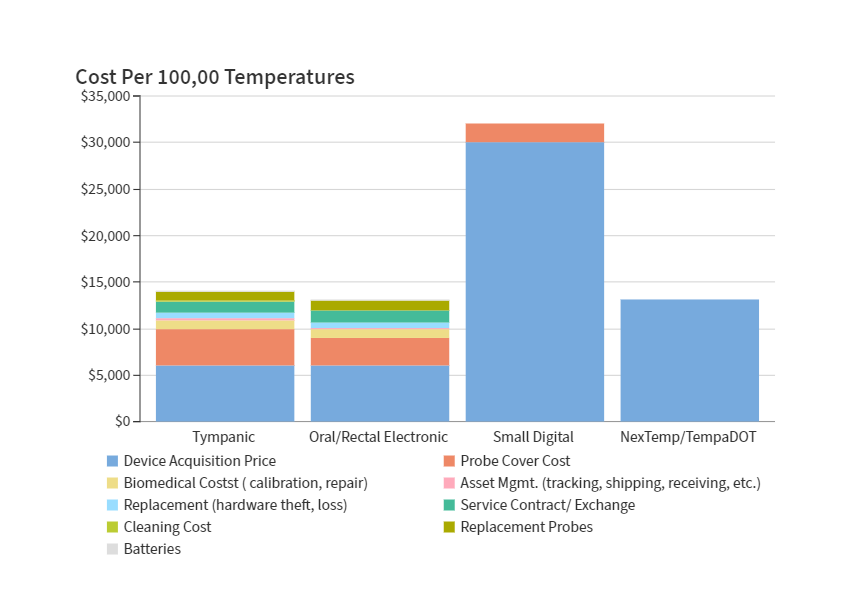

Cost Per Temperature

Aside from helping the environment, facilities using Medical Indicators single-use thermometers also save more than 70% annually compared to Tympanic, Digital/Electronic, Temporal and Infrared Thermometers. Over the course of 100,000 temperatures, our single-use thermometers provide more thermometers, better protection from cross-contamination, and greater savings compared to Tympanic, Digital/Electronic, Temporal and Infrared Thermometers.

Patient Protection

Lastly, when thermometers are used on multiple patients by health care providers, the potential for transmission of pathogens from patient-to-patient and patient-to-provider increases. Though non-contact thermometers have implied infection control benefits, they are actually less accurate and in many cases, not recommended for clinical use. Even with the most stringent cleaning and sterilization protocols, it is nearly impossible to ensure a contaminant-free device for each use.

According to a study published in the Expert Review of Pharmacoeconomics & Outcomes Research, Healthcare-Associated Infections cost hospitals anywhere from $28 to $45 billion a year. The problem of HAIs is complex, and its human toll is tragic. For health care systems the associated financial costs have crippling ramifications, including reductions in Medicare reimbursement for hospitals that score in the bottom quartile on CMS-mandated Hospital-Acquired Conditions (HAC) reviews.

Medical Indicators single-use thermometers virtually eliminate the spread of germs. Thus, virtually eliminating the costs associated with Healthcare-Acquired Infections. The amount of savings from decreasing Healthcare-Acquired Infections is enough to drastically reshape annual hospital budgets. Essentially, when applied to purchasing thermometers, our single-use thermometers pay for themselves by saving you money!

This is achieved since all Medical Indicators single-use thermometers:

• accelerate procurement efficiency as single source item

• decrease risk of capital loss due to theft

• eliminate maintenance and repairs

• offer a low initial acquisition cost

• provide unbreakable, waterproof design

• remove the calibration process

In the end, reusable thermometers create more waste, cost more money, and lead to more HAI cases. Medical Indicators is proud to manufacture the only clinically accurate, single-use thermometer on the market today trusted as both a cost-effective and eco-friendly solution by top hospitals, urgent cares, dialysis clinics, and other leading healthcare facilities worldwide!